polystyrene

Polystyrene (abbreviated PS) is a polymer that is produced by the polymerization of styrene (vinylbenzene). It is widely used, for its thermal insulation and protective properties it is used as thermal insulation and packaging material. It belongs to the group of polyolefins. We recognize two basic types of polystyrene — standard thermoplastic polystyrene (heavy) and expanded polystyrene (light).

Polystyrene is sold under several names: Luran, Lustron, Styropor, Styrodur, Styroflex, and Sagex.

History

Polystyrene was first prepared by accident in 1839 by the German pharmacist Eduard Simon. During the distillation of styrax (Liquidambar orientalis resin), he obtained an oily liquid, which he named styrol. A few days later, Simon noticed that the oil had solidified. He assumed that it was the oxidation of styrene by atmospheric oxygen, so he named the solid substance styrene oxide. However, in 1845, the English chemist John Blyth and the German chemist August Wilhelm von Hofmann discovered that the same transformation of styrene takes place even without the presence of oxygen and named the product metastyrene. Later analysis proved that metastyrene and styrene oxide are identical compounds. In 1866, Marcelin Berthelot correctly determined that metastyrene was formed from styrene by polymerization.

Later, it was discovered that just by heating styrene, a chain reaction occurs, the product of which is a macromolecular substance. This fact led to today's name of the compound — polystyrene. The German company IG Farben started producing polystyrene around 1931.

Features

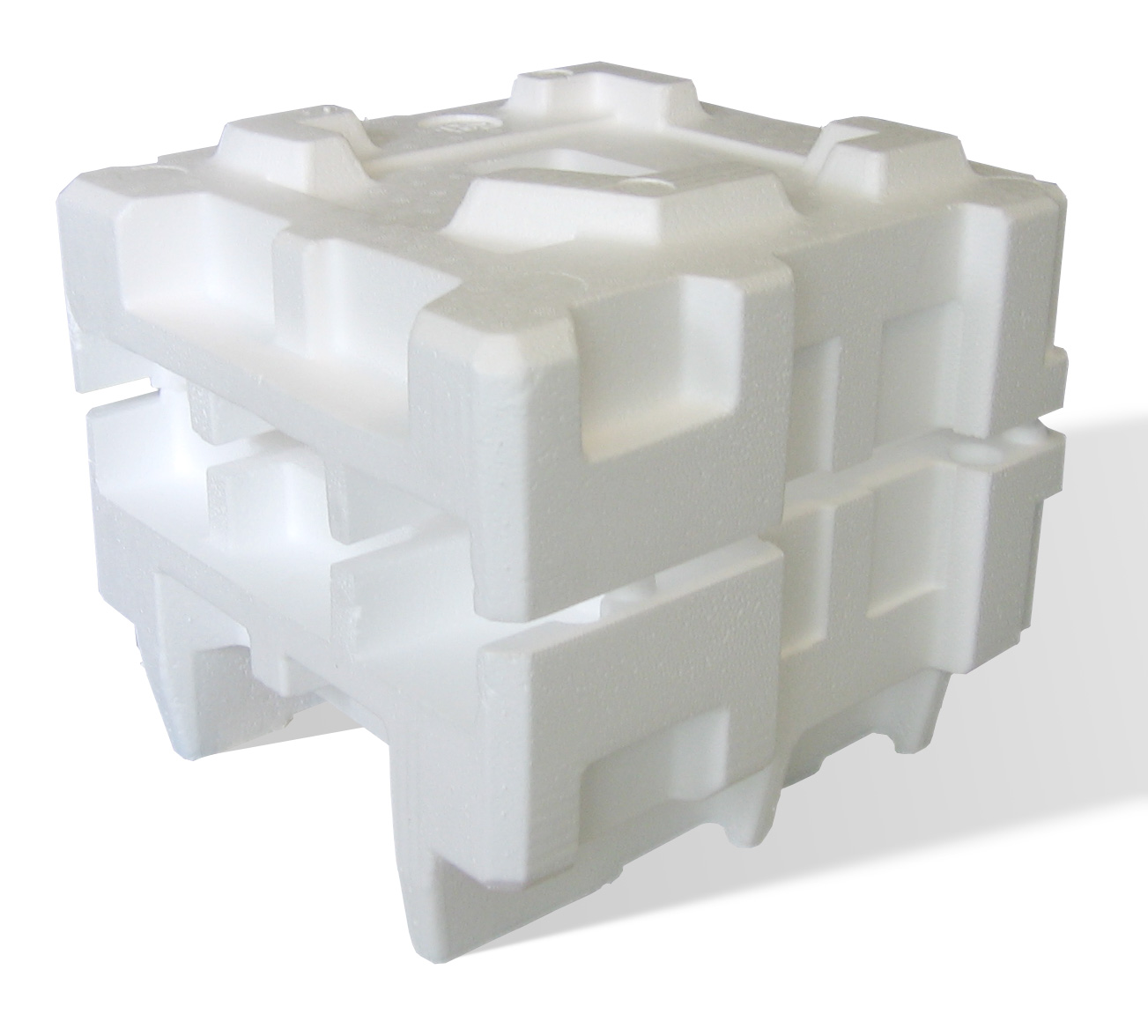

Styrofoam is used as packaging.

Polystyrene is a transparent hard and at the same time very fragile plastic. It is not resistant to gasoline, ketones (for example, acetone) and aldehydes (polystyrene is generally not resistant to organic solvents). In addition, it is relatively sensitive to UV radiation. The density of standard polystyrene ranges from 1.04 to 1.09 g/cm³. For foam, where most of the volume is air, it is only 0.02 to 0.06 g/cm³.

Standard polystyrene is hard, sensitive to impact, and its properties deteriorate quickly with time and weather effects (brittle, creates many cracks). The temperature resistance is also very low — it can be used up to 70°C, but for rapid aging it can only be used up to 55°C. Melting of the crystals already occurs at a temperature of 90 °C, glass transition at 95 °C.

Styrofoam burns with a yellow, very smoky flame accompanied by a sweet benzene smell. Combustion products are harmful to health if inhaled.

Compared to classic polystyrene, expanded polystyrene has even lower mechanical strength and elasticity. It is white, opaque and characterized by very low thermal conductivity and density.